SAS Coffee

SAS Coffee, a family business with a passion for coffee, has specialized in blending, roasting and packaging this delicious product since 1947. That is why they find it important to be able to guarantee the best possible quality. In addition to all kinds of certified quality systems, they simply also have the will to deliver good coffee, excellently packaged to their customers. The specialized cuppers monitor the taste from raw bean to finished product. After a test period, SAS Coffee has also included the Maxxrack stacking frame in its process as an added value to save space and safety.

SAS Koffie nv

Van Dorst Logistic Services

Logistics specialist since 1936 and provides customized storage and transport, with 35,000 m2 of guarded storage near the highway. Satisfied with investing in Maxxrack stacking frames for non-stackable products, almost doubling its capacity with 90% extra storage!

Van Dorst Logistic Services

Broekman Logistics

With international offices, Broekman Logistics offers tailor-made logistics solutions worldwide. We have locations in Western and Central Europe and South and East Asia. Our offices worldwide work closely together. Over the years, we have also built up a strong network of international partners and representatives in the logistics sector.

Broekman Logistics

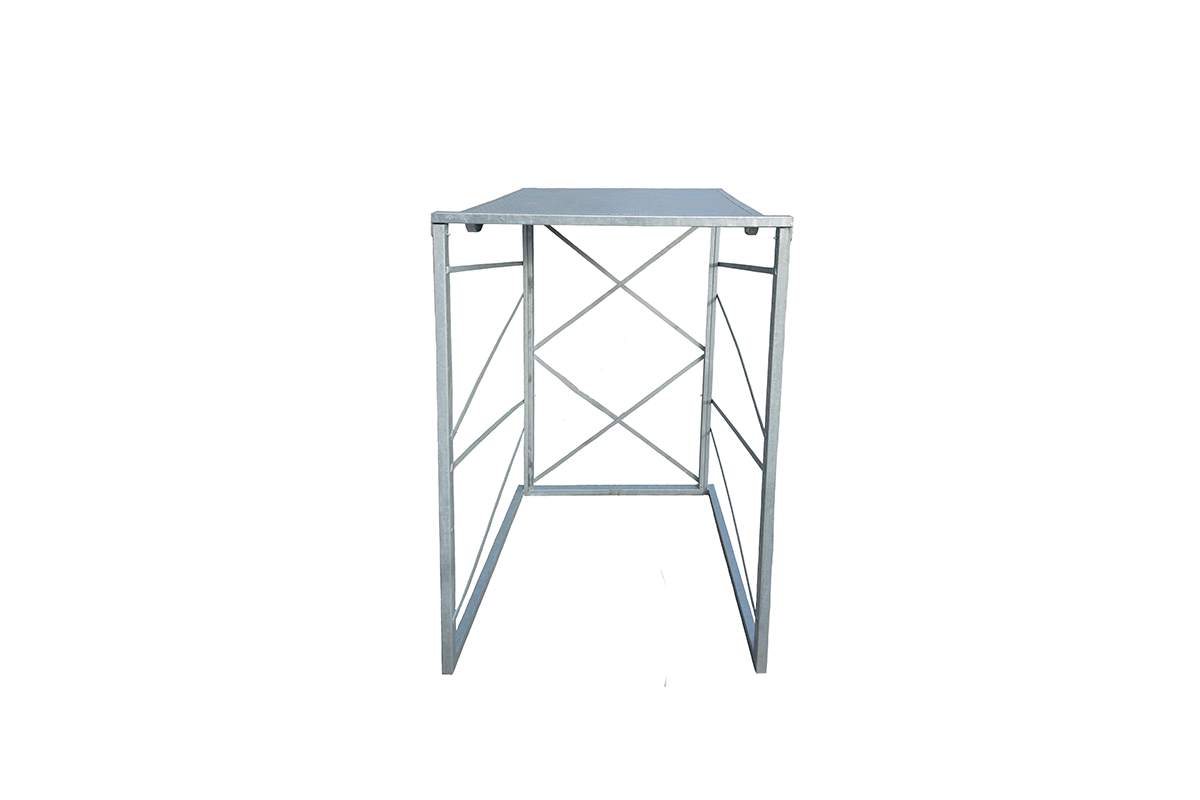

Kempenaars Recycling

Kempenaars Recycling has grown into a state-of-the-art recycling company in Roosendaal. Here, paper, plastics and foils are processed into new raw materials every day using the latest techniques. For storage, Kempenaars has been using the MAXXRACK stacking frames for some time to great satisfaction.

Kempenaars Recycling

RKW Hyplast

RKW Hyplast is located in Hoogstraten (Belgium) and since 2014 part of the RKW Group, one of the world's leading manufacturers of plastic film solutions. The company produces a wide range of polyethylene films for numerous applications in the agriculture, horticulture and construction and process industry. RKW Hyplast uses the MAXXRACK stacking frame for the storage of raw materials in big bags.

RKW Hyplast

RAFF Plastics

RAFF Plastics has been a specialist in plastics since 1976. With 40 years of experience in compounding, extrusion and recycling, the company is today an established international value. Both as a processor and as a supplier of all kinds of recycled plastic. Constant, heavy work has prompted RAFF Plastics to start using an initial order of MAXXRACK stacking frames after a positive test, in order to increase its storage capacity of certain products by 90%.

RAFF Plastics

Plastirec N.V.

Plastirec N.V., founded in Beerse in 1989, specializes in recycling various types of plastic. Plastirec thus offers a sustainable solution for your production waste. A profession in its own right that requires specific know-how. Plastirec is now a well-known international player in its field and is still growing rapidly. To increase the optimal utilization of its storage space, Plastirec has opted for the MAXXRACK stacking frame after a successful test period.

Plastirec N.V.

Pelican Rouge Coffee Roasters

Pelican Rouge is a complete coffee concept. Each Pelican Rouge blend is a result of creativity, craftsmanship and attention. Pelican Rouge sells its products in more than 65 countries. In addition to storage gain, the MAXXRACK stacking frame was also found to be food-safe / food-graded after a strict inspection. In the meantime, the company has already started using another order to its full satisfaction.

Pelican Rouge Coffee Roasters

Morssinkhof-Rymoplast Plastics

Morssinkhof-Rymoplast Plastics is a recycler with a leading role in the European plastics processing industry. Since 2019, this major player has used its warehouse optimally for the 3rd consecutive year with 90% extra storage. Overview and safety are decisive factors.

Morssinkhof-Rymoplast Plastics

Vitafor Belgium

Vitafor manufactures and markets products that improve and protect the performance of animal protein production. They offer a complete range of animal feed ingredients, food products, hygiene products and disinfectants.

"We are extremely satisfied with the Maxxrack stacking frame as an added value for storage gain and safety in our warehouse."

Vitafor Belgium

De Molenbergnatie

The Molenbergnatie, a leading and innovative global player in the coffee industry and forerunner in supply chain management of soft raw materials, has been very satisfied for several years with the Maxxrack stacking frame as an added value in storage efficiency, not to mention safety!

De Molenbergnatie

Loodet

Loodet provides worldwide storage, transfer, silage and repackaging of ADR and non-ADR classified goods, food and feed. MAXXRACKS simplify the entire logistics process of storage, transfer and transport. Loodet now has 7200 MAXXRACK stacking frames in continuous use!

Loodet Storage & Transshipment